K+S has over 300 fully functional test stands which allows our Technicians the ability to fully system test every PLC repair.

This ability allows us to simulate how the unit will operate within a plant environment so we can check for elevated temperature faults.

We go beyond bench testing with a high-tech approach that includes building test stands in “hot boxes” and dynamically testing your PLC components with the actual controllers, under load, in an environmental condition, just like the factory.

During the PLC repair process we find the faults, correct them, retest the component to verify operation and burn them in for a period of 72 hours.

Brands We Service

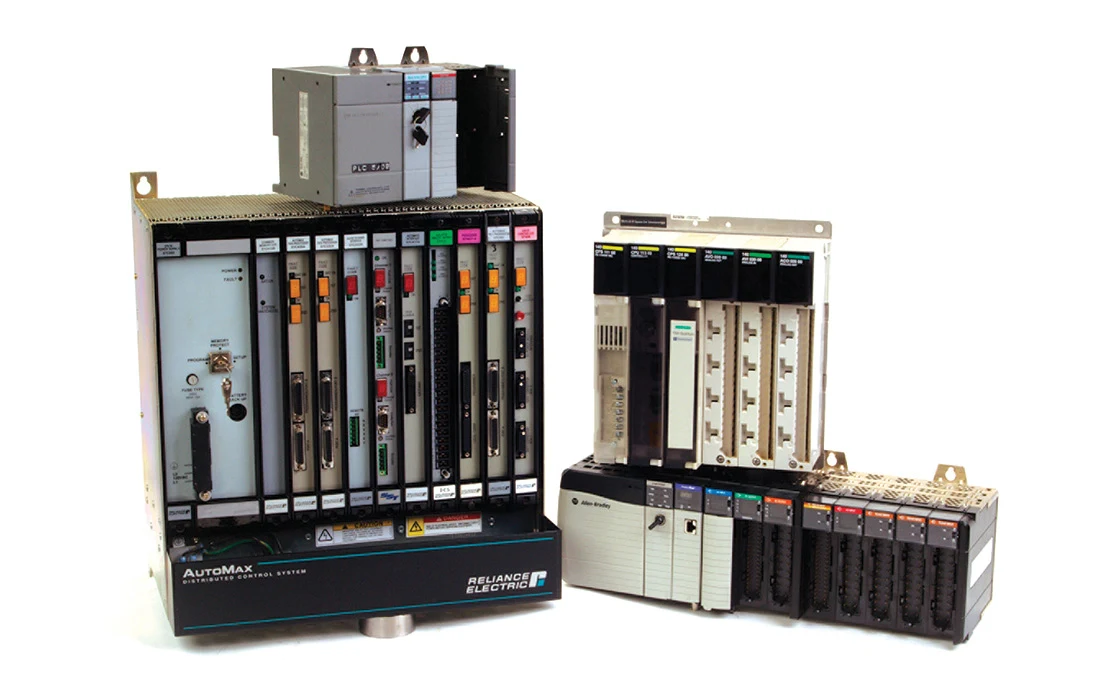

Allen Bradley

K+S Services proudly offers qualified PLC repair services for many new and discontinued Allen Bradley PLCs. All repairs are performed by a factory-trained technician in contaminant-free, heat-sealed enclosures and follow our ISO 9001:2015 quality management standards.

Our state-of-the-art facility also features custom-built dynamic test stands for various Allen Bradley PLC models, including our MicroLogix 1500 test stand with a 1764-24AWA base unit and 1764-LSP, LPR processor module, our PLC 2 system with custom-built diagnostic programs to detect and eliminate common system faults, and our CompactLogix stand which can be expanded to meet customer needs. We test and burn PLCs for 2 to 3 days to reduce intermittent failures. Any faulty components are replaced with OEM components, and if we discover any components that are known to fail, we will replace them as a standard precaution.

Some of the Allen Bradley controllers and systems we conduct PLC repair services include:

- MicroLogix 1000 Series

- MicroLogix 1500 Series

- 1745 Series

- 1746 Series

- 1747 Series

- 1756 Series ControlLogix Modules (for D/C, A/C, & Analog Racks)

- AB 1768 Controllers

- 1768 Ethernet Modules

- AB 1769 Controllers

- 1769 Input & Output Modules

- 1769 Input & Output Modules

- 1771 Series

- 1772 Series

- 1774 Series Controllers

- PLC 3 & PLC 3-10 Systems/1775 Series

- 1785-5 Series A-D (excluding Ethernet)

- 1791 Series

- PLC 2 Systems

- PLC 5 Systems

- PLC 5/250 Pyramid Integrator

- SLC Series

Some of our other manufacturers whose products we conduct PLC repair services for include:

Peripheral Items

- 1791 Series I/O

- 1770-SA

- 1770-SB

- 2700 Series

- 2755 Barcode Family

- 2803 Vision System

- All Starlinks

- Advisor

- Advisor 2

- Advisor 2+

- Intelligent Antenna

- Intelligent Panel System

- M-10 Mass Storage

- M-11 Mass Storage

- M-12 Mass Storage

HONEYWELL

- 620-10, 15, 16, 20, 25, 30 &

- 35 Series

- 621 Series I/O System

- ICP 622

ISSC /IPC

- 90 & 300 Series

MITSUBISHI

- F1 & F2 Series

- Series “A”, “Ann” & “Q”

AUTOMAX / RELIANCE

- AMX 6010, 6011, 7010

- DCS 5000

BAILEY

INFI 90

BARBER COLMAN

- EdacMaco IV

- Maco V

- Maco VI

- Maco 8000

CINCINNATI-MILACRON

- Apc-1 & 500

CUTLER HAMMER

- D-100, 200 & 500

GENERAL ELECTRIC (FANUC)

- 90/20, 30 & 70 Series

- Series One, One Jr., Three, Six,

- Six Plus

- PiC 409 / 49

MODICON

- 184, 384, 484, 584, 884 &

- 984 Family

- Compact 984

- Micro 84

- Micro 984

- PC0984

- Quantum Series

OMRON

- S6 Series

RELIANCE

- Automate

SHARP

- W51

SIEMENS

525, 535, 545, & 555 Series

S5-110, 115 & 150