K+S Services is committed to meeting your “Go Green” initiatives

“Go Green” is on the forefront of many organizations’ pursuit for environmentally friendly product development, promoting energy savings products, and activities. Green guidelines offer recommended measures for conserving natural resources, using water and energy wisely, improving indoor air quality, and planning for livable and vibrant communities. Manufacturing processes which meet these guidelines help reduce environmental impacts and often cost less to operate and maintain.

When it comes to manufacturing, “Go Green” is the right thing to do. K+S is dedicated to working with our supplier partners and customers to design and integrate the most efficient hydraulic, lubrication, process filtration and chip and coolant filtration systems. Focusing on creating more efficient systems, utilizing variable frequency drives (VFDs), along with improving filtration processes by reducing, or in many applications, eliminating disposable media is our mission.

Air Filters

- Mist, Smoke, Particulater

- All the models are ready for both pre-filtration and after-filtration

- Directly installed on the machine tools

- Filtering down to HEPA filtration

- Electrostatic available

Gravity Paper Systems

- Compact Design

- Complete plug-n-play with full electrical panel

- Optional pump

- High flows for all types of fluids

- Filtering down to 5 micron

- Automatic indexing

High Pressure Coolant

- Compact design

- Standard or custom units

- Optional VFDs

- Extend tool life and better part quality

- Complete drawings and manuals

- Wide range of flows and pressures

Magnetic Separator

- Engineered with high power ferromagnetic discs which trap solid contaminants present in coolants or lubricants

- Low running costs

- High Flows

- Ease of installation

- Low cost

Chillers

- Complete line of oil and coolant coolers

- Applications include linear motors, lasers, EDM, high speed spindles

- Capacities from 2,000 to 360,000 BTU/ HR

- Quick delivery

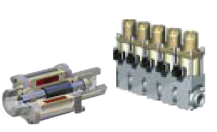

Valves

- Sizes from ¼” to 12”

- Direct operated or pilot operated

- Bubble tight shut off up to a ANSI class 6

- Pressures up to 7500psi

- Any variety of fluids or gasses

- 2/2 or 3/2 valves

K+S Services is Keeping Industrial America Running

K+S Services technicians provide technically sound, cost saving solutions to reduce operating costs and improve plant efficiency. With fluid power expertise in the technologies of hydraulics, pneumatics, industrial automation, lubrication, filtration and service and repair, our goal is to make your plant run more efficiently and improve your bottom line.

K+S Coolant Systems Solutions offers tailor-made solutions and service for the Automotive, Aircraft, Aerospace, Defense, Medical and Bearing manufacturing markets. We offer a complete range of coolant filtration systems, auxiliary equipment, swarf handling systems or stand-alone coolant filters for the individual CNC machine tools or central systems.

Conveyors/Filtering Systems

- Vacuum/Cell Filtration, Standard Hing Belt, Drag-Out Conveyor

- Wipers on belts clean bottom pan surface a minimum of two times per revolution

- Continuous operation

- Ball-detent clutch system

- 100% unattended machining operation

- No cartridges or bags to change

Centrifugal and Vortex Pumps

- High Pressure Pumps-Screw, Diaphragm, Piston Pumps

- Flows up to 6000gpm

- Pressures to 10,000ps

- In-line or vertical mounted

- Self Priming

- High solids handling

- Chip breaking capabilities

- Variable frequency drives (VFDs)

Liquid Bag Filters/Housings/Strainers

- Housing are engineered to effectively remove dirt, pipe scale and other contaminants from process liquids

- Strainer basket is available in various opening sizes

- Higher pressure ratings 100, 150, 300 to 3000 PSI

- Flows up to 4300gpm for a single housing

Tramp Oil Removal

- Floating Head/Coalescing Skimmer Disc Skimmers, Belt Skimmers

- Extended tool life

- Improved parts finish

- Smoke & odor eliminated

- Multiplied coolant life

- Less machine downtime

Self Back Flushing Filters

- Barrier Type Media, Cyclonic Filtration, Magnetic

- Low life cycle costs

- No filter material is consumed

- Cleaning without interrupting flow to process

- Efficient filter cleaning assures maximum process stability

- Filtering down to 5 micron

Pump Back Systems

- Capable of pumping full chip loads from machine to central coolant systems

- Easy change from single filter units to central coolant cleaning and supply

- No more expensive costly in-floor flumes

- Flexibility to relocate machine tools