K+S Featured in Manufacturing in Focus Magazine

Quality Repairs & Predictive Maintenance, written by Jen Hocken.

K+S Services established itself in 1982 by repairing electronic circuit boards for the automotive industry, and since that time the company has expanded it’s capabilities to meet the needs of its diverse current customer base. It has grown to include repair services for motors, high speed spindles, DC torque tools, valves, vacuum pumps, blowers, robotic welding apparatus, electronic servo and variable frequency drives, HMIs and numerous other mechanical, hydraulic, electronic, and industrial components.

Today, K+S Services employs over 500 people worldwide and has 22 facilities located in Canada, the United States, Mexico, the United Kingdom, Belgium, Czech Republic and Poland.

The core business of K+S is repair services of the sub components of industrial automation equipment and although it assists its customers in finding solutions to repair obsolete or antiquated equipment, the company is not in the business of providing complete MRO sourcing solutions. The majority of its competitors are in one category of either electronic, mechanical, or hydraulic repairs; K+S provides a full turnkey solution by covering all of those markets.

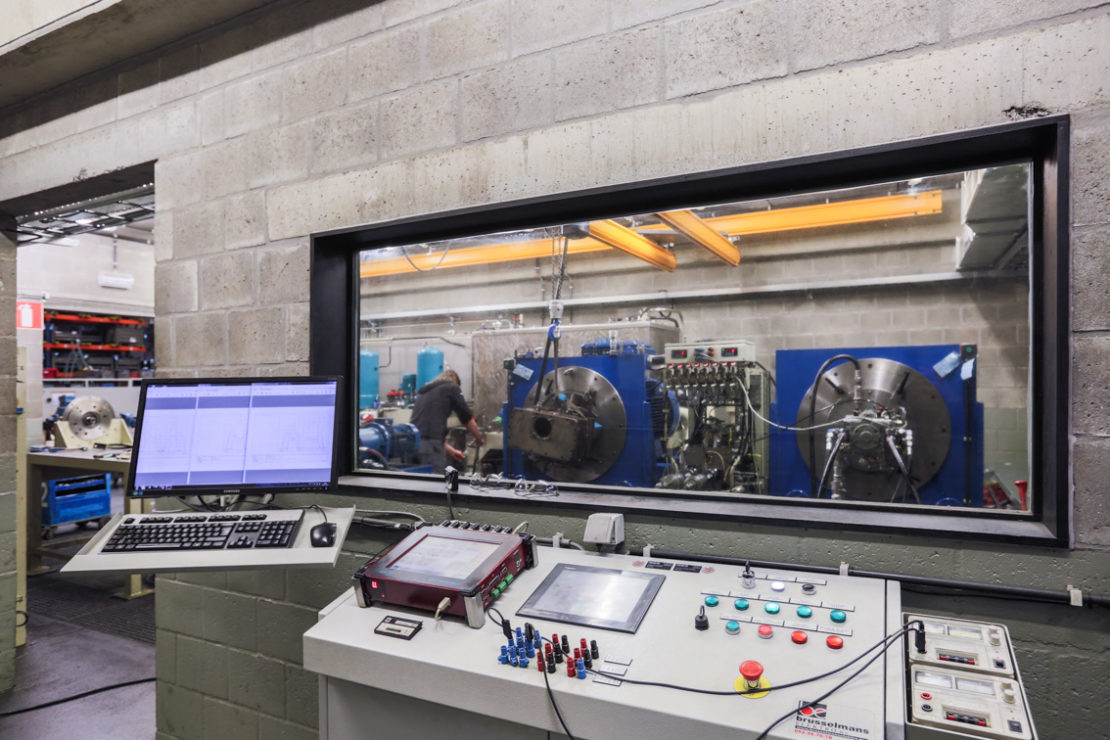

“We don’t just repair; our philosophy at K+S is to refurbish the customer’s components to a like new condition. During the refurbishing process preventative maintenance is also performed on known high failure rate items. Final testing is performed in a closed loop environment to ensure the refurbished component meets OEM standards and the customer’s needs. We also believe that if we don’t have a functional test capability for that repair, we don’t consider it repaired,” says Dick Puhl, Director of Sales.

“K+S prolongs the useful life of equipment and allows its customers to avoid costly capital expenditures.”

There are four separate companies that fall under the K+S umbrella. Superior Spindle Services, located in both Taylor, Michigan and Monterrey, Mexico, repairs machine tool spindles. Encore Systems repairs DC torque tools and controllers, and provides tool management services, with facilities in Brookville, Ohio; Oakville, Ontario; Monterrey, Mexico; Salamanca, Mexico; and soon to be in the United Kingdom. Kennedy Repair Services is based out of Troy, Ohio and specializes in the remanufacturing of weld guns and robotic welding apparatus and Aztechnology is a Michigan registered Minority Business Enterprise partner of K+S that also repairs and provides asset management services.

K+S is factory trained and authorized to repair products for Siemens in Canada and Mexico. K+S has been awarded other authorizations by Fronius, Miller and Lincoln welders, and LSIS products. K+S represents Star Valves in all of North America for new sales, repairs, and warranty service.

K+S prolongs the useful life of equipment and allows its customers to avoid costly capital expenditures by supporting obsolete equipment for as long as possible. The budgets of manufacturing companies in all arenas have been cut back, particularly in the automotive industry, but fortunately, K+S is able to service these customers with its S.T.A.M.P. repairable asset management program to help with uptime and decrease the overall cost of ownership.

“The foundation of professional service offerings we provide is our asset management program, where we’re fully embedded into a manufacturing plant with onsite people. We collect data surrounding equipment failures, mean time between failure, exceptional usage and then frequently present to the plant staff to help them drive their reliability and cost savings opportunities,” says Puhl. K+S can also provide dedicated reliability engineering and predictive services to demonstrate to the customer where their failures are and where they are losing production time.

“We provide root cause analysis for failures based on component, machine or process oriented losses to help our customers increase their OEE by making data driven decisions. We are then able to provide a number of different solutions to help them once those decisions are made,” explains Charles Gauss, Vice President.

The use of predictive and preventative maintenance is becoming more prevalent in the industry because it allows a manufacturer to fix potential problems before they occur and keep the operation up and running consistently rather than having to pause and repair a component. Vibration analysis, thermography, and tribology are all techniques used for predictive maintenance. K+S has the ability to put a predictive and preventative maintenance program together for its customers based on its observations or to help augment their existing program.

“In the past, we were strictly measured on the cost of new versus refurbishment and moving forward it’s really about, ‘how do we help [customers] improve their OEE while also saving them money?’ We’ve always done a great job on the repair side; now we need to bring more value to our customers on the predictive side to help them with their uptime,” says John Willis, Chief Operating Officer.

K+S designs custom solutions for its customers by conducting a value management study to address their concerns. Reliability engineering, predictive and preventative maintenance routines, upfront engagement (industrial bill of material evaluation and warranty tracking) and storeroom solutions are all combined when necessary to create the most efficient operation possible for the customer. “There are different levels of our onsite services. We cater to the requirement of the customer; if they need help running their storeroom as well as an asset management program, that is something that we provide as well, it just depends on their needs,” says Willis.

The manufacturing industry as a whole is experiencing a skilled trades shortage that is creating more opportunities for K+S to assist its customers by filling that gap. The skilled trades shortage is something K+S is also experiencing. To address this challenge, K+S has partnered with the state of Michigan to participate in one of its most active and successful workforce programs, MAT2 (Michigan Advanced Technician Training, or MAT squared). The Michigan Talent Agency and Henry Ford College joined together to afford students the opportunity to earn an associate degree in mechatronics or computer numerical control (CNC) that is fully funded. The MAT2 program enables students to begin a career right away and get paid while attending school, which is a great way to attract more numbers to the depleting workforce.

The MAT2 program has proven highly successful for K+S; in fact, it was one of the largest employers of mechatronics students in the state of Michigan for the last two years. The two-year degree takes three years to complete while alternating semesters between school and work and the student signs a contract to stay with K+S for an additional two years after graduation while of course being paid a competitive wage. The company is looking forward to continuing its relationship with the MAT2program moving forward.

“The use of predictive and preventative maintenance is becoming more prevalent in the industry because it allows a manufacturer to fix potential problems before they occur.”

“We are in a very unique type of industry,” says Gauss. “It’s not like we can go pick somebody up anywhere that knows how to refurbish complicated manufacturing parts at a sub-component level, so this program has worked very well for us and we know it will take us into the next 10 to 20 years. That’s the main way we’re handling the skilled trades issue on our end.” K+S also gets involved in the trade schools and local municipalities in every location to ensure that it takes advantage of every opportunity available and grows its team to its full potential.

K+S knows the strain an aging skilled trades workforce can have on its customers and it understands the supplier to customer relationship is strengthened when a true partnership is formed. To that end, K+S even hosts onsite training sessions with its customers’ maintenance staff to raise awareness about how to properly install or replace equipment and how to use predictive maintenance to reduce the amount of unplanned downtime on their own. This type of extra effort is one of many ways the company demonstrates its commitment to the success of its customers. In the future, K+S Services will continue to follow through with its mission to provide quality repairs, effective solutions, and efficient service worldwide.

Click here to read the article in the Manufacturing in Focus Magazine. Article written by Jen Hocken